30 May How Scientific Advances Can Help Water Companies Meet AMP6 Targets

Posted at 13:46 in Resilience by Rene Willemsen

In my past couple of articles I’ve been focussing almost exclusively on the critical role Totex and asset resilience both play in delivering against and outperforming ODIs for AMP6.

While I cannot overstate how important these are to meeting targets and maximising future budgets for the next Asset Management Period (AMP), I’m also aware that there are those keen to understand the practicalities of making key assets and infrastructure more resilient.

As a result, I’d like to outline some key innovations in the market right now, touching on the science behind their effectiveness and how they are currently helping water companies ensure the resilience of assets in line with AMP6 ODI targets.

Protective Polyurea Coatings

In AMP6, water companies are being judged on how they deliver against a number of customer focussed outcomes.

This customer focus essentially means that interruptions to supply, leakage, and pollution incidents are especially dangerous.

Fortunately, today’s polyurea coating technologies can mitigate all of these risks, providing an added layer of protection to non infrastructure assets from telemetry stations and pumping stations; to sludge, chemical, and fuel storage tanks.

Typically used for asset refurbishment, secondary containment, and flood mitigation, these coatings essentially create an impermeable barrier that prevents adverse interactions between essential processes and the environment. More importantly, polyurea coatings also provide significant structural reinforcement for vulnerable assets and ageing infrastructure; extending operational life by at least ten years to help water companies meet ODIs.

As I’ve argued before, the cost of investing in this kind of resilience measure is negligible relative to the costs of capital replacement or worse still, doing nothing.

Aside from the low initial cost, the key selling point of polyurea coatings for water companies is the ease and speed of application. Virtually unaffected by high humidity, temperature and residual moisture during and after application, these coatings can be applied with minimal disruption to service, drying almost instantly without releasing any harmful pollutants or VOCs.

This provides water companies with an opportunity to not only restore vulnerable or out-of-operation assets to their former states, but to effectively develop resilience across all critical assets as a preventative measure before these begin showing signs of age and vulnerability. Achieving this through more traditional methods such as capital replacement would invariably incur considerable front-loaded costs, not to mention disruption, downtime necessitating the costly provision of temporary works to avoid service failures, and potential funding cuts in the next Asset Management Period.

JBAR®

Designed to protect and extend the life of key assets through class-leading environmental containment and flood mitigation, JBAR® is our unique, patented, flood defence system, suitable for protecting DNO substation assets and a wide range of water and wastewater assets.

As with protective polyurea coatings (which incidentally work extremely well together to provide an added layer of protection), the strength of JBAR® lies in its ability to offer low cost, high performance resilience with a rapid speed of installation that negates downtime to ensure ongoing serviceability.

While I’m sure there are other solutions of a somewhat similar function available on the market (that is, offering two-way protection against food water ingress and leakage of pollutants) what makes JBAR® special is its modular properties and versatility; accounting for a bund build cost reduction of up to 45% and average reduction of time on site by over 80% when compared to traditional civils based solutions.

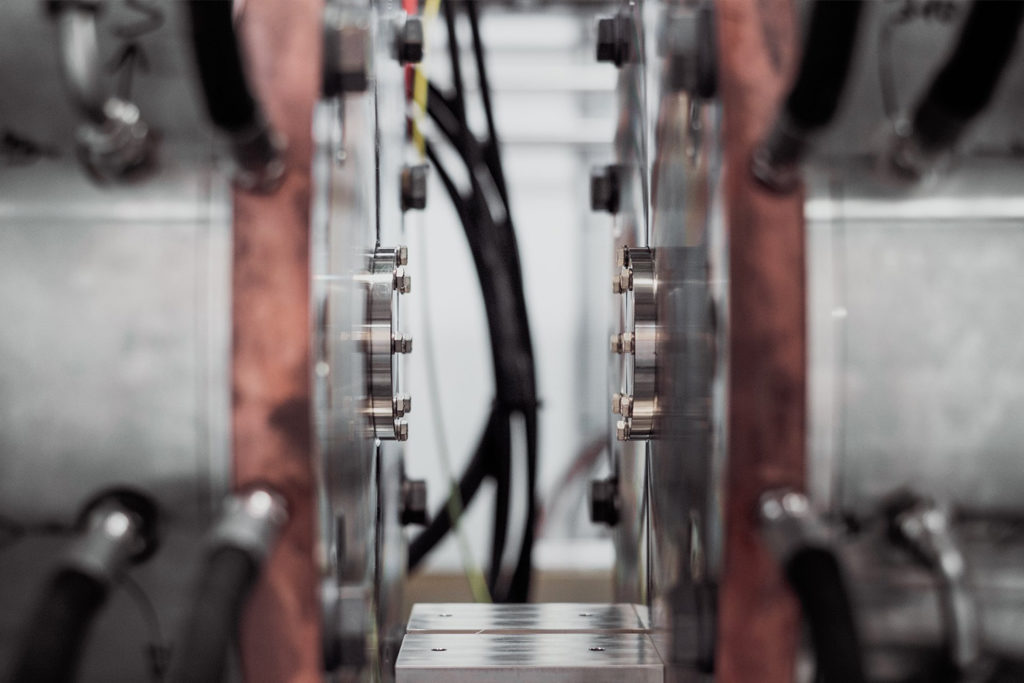

Cathodic Protection Solutions

While ageing infrastructure remains a major concern for utilities, corrosion is especially threatening for water companies given many of their assets are in contact with electrolytes via sea, groundwater, and rivers by default.

This isn’t a new problem of course, and consequently many cathodic protection solutions were installed decades ago as ‘fit and forget’ systems. The problem with this approach however, becomes clear after 20 to 30 years when organisations have either forgotten about the investment altogether or have limited knowledge on the state of their assets, leading to serious yet avoidable detrimental impacts on existing pipeline and outfalls. With cathodic protection systems only designed to last 20 to 30 years, organisations must adopt a new approach to monitoring vulnerable assets, pipelines, and infrastructure; preventing them succumbing to corrosion as system come to the end of their lives.

This is where I believe the potential for innovation lies.

While the science behind cathodic protection solutions remains largely the same, I believe it is in how organisations use them and monitor their impacts on assets that water companies can more effectively protect assets.

For an in-depth explanation of our cathodic protection solutions and the science that drives them, click here.

The Key To AMP6

As with any scientific advance or innovation, the strides being made in asset protection are only as promising as the way they’re applied to solve practical problems. For water companies looking to meet and outperform ODIs, I believe this means placing customer outcomes first by building resilience and serviceability into each and every asset. What this demands is a movement toward more holistic, Totex-driven investments; it demands that you consider whole life cost and stewardship ahead of Capex investment; it demands that you start thinking about customer service as more than direct interactions on the phone.

Tim Farley is Utility Resilience Advisor at Adler & Allan, working collaboratively with water companies, contractors and industry forums to promote innovative solutions that deliver AMP6 outcomes.

Tim Farley

Asset Resilience Specialist offering Totex contracting solutions for Utility sector.